- India’s Leading Industrial Solution Provider

- CE-BG 10 Multi Packaging Machine

- PNEUMATIC FFS CHUTE MACHINE CUP FILLER

- PNEUMATIC FFS CHUTE MACHINE 1 HEAD WEIGH FILLER

- PNEUMATIC FFS CHUTE MACHINE Manual CONVEYOR FILLER

- FFS OIL PACKAGING

- FFS MILK PACKAGING

- RUSK PACKAGING MACHINE WITH AUTO FEEDER

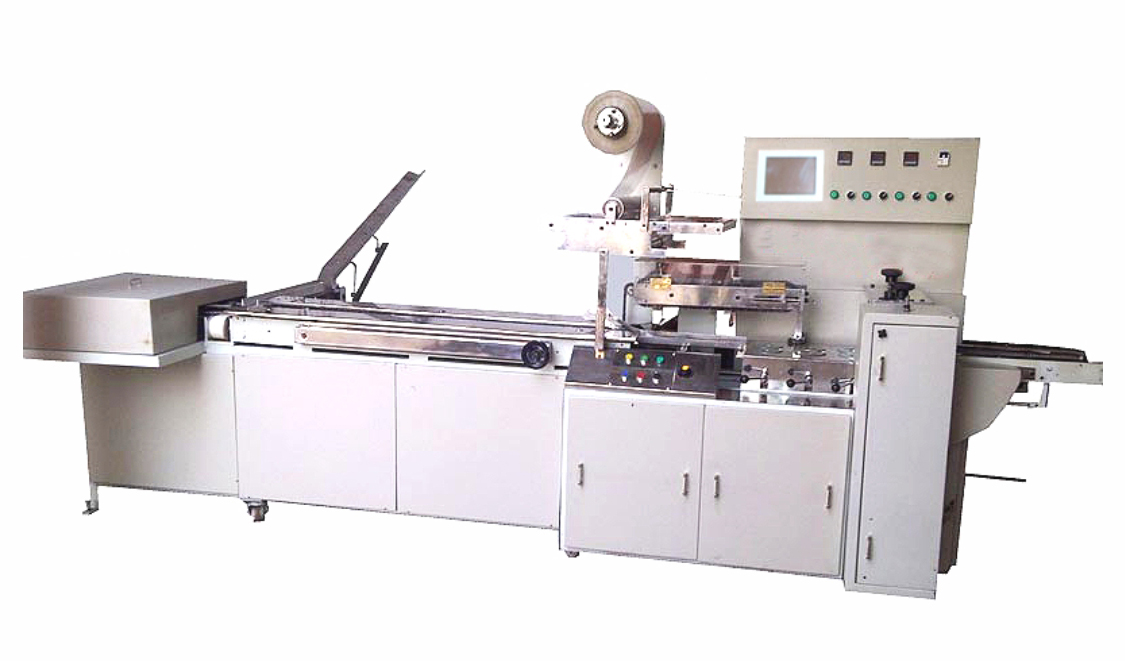

- FLOW RAP PACKAGING MACHINE

- PNEUMATIC FFS CHOLAR AUGER FILLER

- AUTOMATIC FFS MACHINE FOR LIQUID

- AUTOMATIC FFS MACHINE FOR PASTE & LIQUID

- AUTOMATIC FFS MACHINE FOR ICE CANDY

Categories

| Drive | Ac drive / servo drive |

| Motor | 2 hp 220v single phase |

| Diameter roller | 6no (4 cold & 2 hot) |

| Sealer | 2 pieces |

| Diameter roller | 6 pieces |

| Controllers | p.i.d |

| Sealers body | can be adjusted up and down as per requirements |

| Control | plc |

| Line change | Gear system |

| Weighing | Number of pieces only |

| Feeding | Single feeder in the machine |

| Machine dim | 13 l-5w-h5 (feet) |

| Weight | 700kg - 800 kg apx |

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 80/90/100mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 2 KW, Weight : 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

| Filling Range | 200ml to 300ml |

| Maximum output | 1000 to 1500 pouches per hour |

Product Range

Milk, Butter Milk, Juice Water, Liquids

Filling Range

200ml to 1ltr.

Maximum Output

10000 to120 Pouches per hour

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm - Min : 240 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Ele. Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power | 2 KW, Weight : 200-300 Kg(App) |

| Dimension | D : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

Feature

Fully automatic Operated Mechanical machine with latest pneumatics injection system. As per customers requirement REQUIRED ATTACHMENT cooling water Requirement 200 Lts / Hour @ 5 degree centigrade.

| Model | CT AC-6B10HEAD-2B-01X |

| Filling/Weighing Range | 5g-2Kg* |

| Packaging Speed | 40-70 PKT/MIN |

| Control | PLC Control |

| Operation | Pneumatic |

| Reak Core Dia | 70-76-MM |

| Heating System | Hot Bar Induction Heating |

| Electric Required | 420v,3ph, 50hz |

| Material Loading | bucket elevator/hopper* |

| Compressed Air Required | 2cfm at 6 bar pressure |

| Dimension (approximate) | 1800w x 1800l 360oh [mm] |

| Availability in Variety of Models | 5g - 200g* 200g - 1kg* 1kg - 2kg* |

| Packaging Film Size (mm) | w:200 to 500* l:30 to 250* |

-

Main Features

- The most efficient and accurate weight calculation by computer when compared to manual process

- Stager Dump avoid bigger items pile up

- User friendly touch screen equipped with multiple language

- Compatible with single packaging machine for automatic weighting

- Adjustable back light control for vision protection

- 99 present program for multiple tasks

- Instant hopper vibration index for better control

-

Special Features

- Stable Operation

- Antitrust and dust proof design, full 304 stainless, ss with powder coated baby surface to choose from.

- User friendly and multiple language display touch screen controller. Optional 1.3 litre, 2.5 litre buckets

- Compatible with single packaging machine for automatic weighting

- Adjustable back light control for vision protection

- 99 present program for multiple tasks

- Instant hopper vibration index for better control

APPLICATIONS :-

For packing various powders : Curry Powder, Coffee Powders, Spices, Pesticides, Atta, Maida, Detergent powder, Snuff Powder, Milk Powder, Masala, Hair Dye Powder, Pepper etc..

| Model | ct ac-6b10head-2b-01x |

| Filling/weighing range | 5g-2kg* |

| Packaging speed | Plc control |

| Control | Plc control |

| Operation | Pneumatic |

| Reak core dia | 70-76-mm |

| Heating system | Hot bar induction heating |

| Electric required | 420v,3ph, 50hz |

| Material loading | scrue loader |

| Compressed air required | 2cfm at 6 bar pressure |

| Dimension (approximate) | 1800w x 1800l 360oh [mm] |

| Availability in variety of models | 5g - 200g* 200g - 1kg* 1kg - 2kg* |

| Packaging Film Size (mm) | w:200 to 500* l:30 to 250* |

Product Range

Non-free Flowing

Powders such as

Spices, Soup Mixes,

Detergents, Yeast,

Desserts, Coffee,

Flour (Atta),

Rice Powder,

Cocoa Powder,

Ground Spices,

Agricultural Powders,

PNEUMATIC FFS CHOLAR

AUGER FILLER

Product Range:

Non-free Flowing

Powders such as

Spices, Soup Mixes,

Detergents, Yeast,

Desserts, Coffee,

Pharmaceutical &

Flour (Atta),

Rice Powder

Agricultural Powders,

Cocoa Powder,

Chocolate,

Ground Spices.

| Model Available | 10g*-2kg* |

| Packaging Speed | 25-50 Pkt/ Minute |

| Film Width | 60 mm -500 mm* |

| Film Length | 60 mm - 300 mm* |

| Controlled | PLC controlled with LCD |

| Operation | PNEUMATIC |

| Heat System | Hot Bar Induction Heating |

| Motor Power | 2 ,11/2,1Hp |

| Heater Load | 350 W X 4 No |

| Material Loading | Screw Loader |

| Compressor Air Req. | 2 Cfm Ar 6 Bar Presser |

| Demission Apx. | 1800Wx1800L3600H(mm) |

| Control | Plc control |

| Motor | 1/2 hp, 1/2 hp (conveyor) |

| Mode of operation | Pneumatic |

| Weighing | Manual weight (2lab:req) |

| Heating system | Hot bar induction heating |

| Coding | Pneumatic |

| Packing material | Laminated films |

| Power required | 420v, 3ph, 50hz, 5hp |

| Compressed air | 2cfm at 6bar pressure |

| Max. output | 15-25 packs/min |

| Film size (mm) | w 60-360 l 30-250 |

| Weighing range | up to 25g - 250g* |

| Weight | 400kg |

| Model | CPM-PS-001 |

| Filling/weighing range | 5g-500g* |

| Packaging speed | 20-40 pkt/min |

| Control | Plc control |

| Operation | Pneumatic |

| Packaging material | Laminated film |

| Reak core dia | 70-76 mm |

| Heating system | Hot bar induction heating |

| Motor & power | 1/2 hp 220v ac single phase |

| Heater load | 50 watts x 4 no. of heaters |

| Material loading | Manual, scrue / vaccum loader |

| Compressed air required | 2cfm at 6 bar pressure |

| Dimension (approximate) | 1800w x 1800l 3600h (mm) |

| Availably in variety of models | 5g-200g* 200g - 500g* |

| Packaging film size in (mm) | w: 200 to 360* l: 30 to 250* |

| Drive | Ac drive / servo drive |

| Motor | 2 hp 220v single phase |

| Diameter roller | 4no (2 cold & 2 hot) |

| Sealer | 2 pieces |

| Diameter roller | 6 pieces |

| Controllers | p.i.d |

| Weighing | number of pieces only |

| Feeding | Manual |

| Machine dim | 3120 l-1150w-h1580 (mm) |

| Weight | 400kg - 500kg apx |

Specifications

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm - Min. = 240 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal or Side Seal Pouch |

| Electrical Supply | 230 V/A.C./Single Phase/50 Hz |

| Power consumption | 2 KW |

| Weight | 600 Kg. (Approx) |

| Dimension | Depth:850mmW,910mmH,230 L |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

Filling Range

200ml to 1Ltr

Maximum Output

1000 to1200 Pouches per hour

Feature

Fully automatic Operated Mechanical machine with latest technology injection system. As per customers requirement REQUIRED ATTACHMENT cooling water Requirement 200 Lts / Hour @ 5 degree centigrade, Servo Stabilizers.

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 2 KW, Weight : 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

| Filling Range | 200ml to 300ml |

| Maximum output | 800 to 900 pouches per hour |

| Packing Material | Heat sealable LAMINATED films |

| Feeding System | Pneumatic |

| Roll Width: Max | 90/200mm |

| Sealing Type | Hot Bar |

| Pouch Type | Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Weight | 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L |

| Accuracy | +/- 2% |

| Filling Range | 1g to 200g |

| Maximum output | 800 to 900 pouches per hour |

| Packing Material | Heat sealable LAMINATED films |

| Feeding System | Pneumatic |

| Roll Width: Max | 90/200mm |

| Sealing Type | Hot Bar |

| Pouch Type | Side / Center Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 3KW |

| Weight | 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L |

| Accuracy | +/- 2% |

| Filling Range | 1g to 200g |

| Maximum output | 1000 to 1200 pouches per hour |

Product Range:

All kinds of Snacks*

Mixtures,

Sweet Ball,Ground Nuts,

Masala Ground Nut,

Dahashamini,

Rice Flakes

Special Features

PLC controlled machine with

LCD display & touch screen.

Built in self fault diagnosis

Systems.

| Model Available | 10g-250g |

| Packaging Speed | 10 Pkt/ Minute |

| Film Width | 60 mm - 380 mm* |

| Film Length | 60 mm - 260 mm* |

| Controlled | PLC controlled with LCD |

| Operation | PNEUMATIC |

| Heat System | Hot Bar Induction Heating |

| Motor Power | 1/2 Hp 220v |

| Heater Load | 350 W X 4 No |

| Material Loading | Manual |

| Compressor Air Req. | 2 Cfm Ar 6 Bar Presser |

| Demission Apx. | 750Wx750L3600H(mm) |

Applications

For packing various

liquids & Pastes, Oils,

Such As Shampoo,

Soya milk, Butter, Jams,

Mayonnaise, Pickle,

Tomato Ketchup,

Limepaste, Lubrication

Oils etc.

| Model Available | 2ml-100ml |

| Packaging Speed | 20 Pkt/ Minute |

| Film Width | 60 mm - 150 mm* |

| Film Length | 60 mm - 100 mm* |

| Controlled | PHOTO CELL |

| Operation | Mechanical |

| Heat System | Hot Bar Induction Heating |

| Motor Power | 1/2 Hp 220v |

| Heater Load | 350 W X 4 No |

| Material Loading | Manual |

| Demission Apx. | 750Wx750L3600H(mm) |