- India’s Leading Industrial Solution Provider

- Automatic Candy Bar Production Line

- Automatic Candy Ball Production Line

- SEMI AUTOMATIC PEANUT CANDY BAR PRODUCTION LINE

- AUTOMATIC COOKING & MIXING MACHINE

Categories

Product Range :CHIKKI BAR, SESAME BAR, SEVA BAR

-

Specifications

- Vessel : Size: 1000 T X 750 B (mm)

- Motor : 2 Hp 440V Three Phase Gear

- Burner : Gas Burner 5" 4 Nos

- Maximum Output : 15Kg / Batch.

- Blade : Teflon

- Chase : MS

- Body : SS 304

Candy Range :Rice Candy, Peanut Candy, Seed Candy, Corn Cakes, Black Rice Cakes and a Variety of Granular Products

Main Properties and Structure characteristics

Main Properties and Structure characteristics

- The machine adopts microcomputer control, automatic correct dimensions

- Automatic feeding, levelling, chop

- Recruitment, high yield

- Transmission system concise, clear

Longitudinal Slitting

- The rotatory knife(blades) shaft with its own pneumatic Travelling

- According to product size, we will make one set or two sets cutter blades.

- The material of cutter blade:SS 304 Steel. NON STICK COATED.

- Diameter of blade: 100MM. We will make it according yours SIZE*

- Has safety cover.

- MODEL 300

- Capacity: 1 - 1.5 T/8h,*

- Voltage: 380v

- Power: 2kw,

- Motor : 1.5 Hp 440V Three Phase Gear

- Motor : 0.5 Hp 440V Three Phase Gear

- Pressure: 6bar

- MODEL 450

- Capacity: 2 - 4 T/8h,*

- Voltage: 380v

- Power: 3Kw,

- Motor : 2 Hp 440V Three Phase Gear

- Motor : 1 Hp 440V Three Phase Gear

- Pressure: 10 bar

Product Range

Milk, Butter Milk, Juice Water, Liquids

Filling Range

200ml to 1ltr.

Maximum Output

10000 to120 Pouches per hour

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm - Min : 240 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Ele. Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power | 2 KW, Weight : 200-300 Kg(App) |

| Dimension | D : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

Feature

Fully automatic Operated Mechanical machine with latest pneumatics injection system. As per customers requirement REQUIRED ATTACHMENT cooling water Requirement 200 Lts / Hour @ 5 degree centigrade.

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 80/90/100mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 2 KW, Weight : 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

| Filling Range | 200ml to 300ml |

| Maximum output | 1000 to 1500 pouches per hour |

Candy Range :Sesame Ball, Rice Ball, Peanut Ball, Seed Ball and a Variety of Granular Products

MD-500 Automatic continuous molding machine (2-3T/day)

Characteristics:

MD-500 Automatic continuous molding machine (2-3T/day)

Characteristics:

The shapes produced can be various, for instance, round type, round bar, square type, semi-circle type, triangular type. Mechanical soft pressure will mot damage nut particles with more elegant molding. Direct mould pressing and molding can be tree from rework, which saves materials coat and wastes. All the moulds and hoppers have been conducted with anti-stick disposal. The length of the cool conveying links can be changed or cooling fan can be equipped based as required, so as to enhance the cooling effect

-

Main properties and structure characteristics:

- The machine adopts microcomputer control, automatic correct dimensions

- Automatic feeding, Levelling, chop

- Recruitment, high yield

- Transmission system is concise, clear

- MODEL: B-300

- Capacity: 300 bal /min,(Only One Size Ball)*

- Voltage: 380v

- Power: 4kw,

- Motor : 2 Hp 440V Three Phase Gear

- Motor : 1 Hp 440V Three Phase Gear

- Pressure: 10 bar

Product Range :CHIKKI BAR, SESAME BAR, SEVA BAR

Maximum Output200Kg / Hour( Depending Up On Size)

-

Features

- Design Mechanically

- With Manual Reverse Forward Switch

- Easy Lubrication System

- Feed - Manual

-

Specifications

- Cutting : Size: 400 W X 600 L (mm)

- Motor : 1.5 Hp 440v Three Phase

- Motor : 1/2 hp 440v Three Phase

- Roller : Teflon Coated & Nylon

- Blade : SS

- Boady : SS

- Weight : 500kg

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris ac egestas magna. Morbi mattis lectus eget velit iaculis elementum. Sed nec risus euismod, tristique urna posuere, elementum tortor. Integer egestas enim sit amet augue rutrum euismod. Curabitur scelerisque id leo non blandit. Aliquam eget erat a magna ornare viverra. Nunc sit amet eleifend felis.

Suspendisse varius elit libero, id pellentesque dui malesuada sed. Fusce at nisi leo. Donec pellentesque accumsan ex, eget tempus nibh tincidunt non. Sed vel fermentum augue. Aliquam condimentum, turpis quis cursus dignissim, lacus metus feugiat leo, ultrices faucibus velit justo sed turpis. Integer neque dolor, ornare vitae dui nec, aliquet porta tellus. Praesent mattis interdum tincidunt. Aenean ac ultricies diam. Proin egestas libero purus, malesuada consequat orci ullamcorper a. Donec facilisis tincidunt velit at dictum.

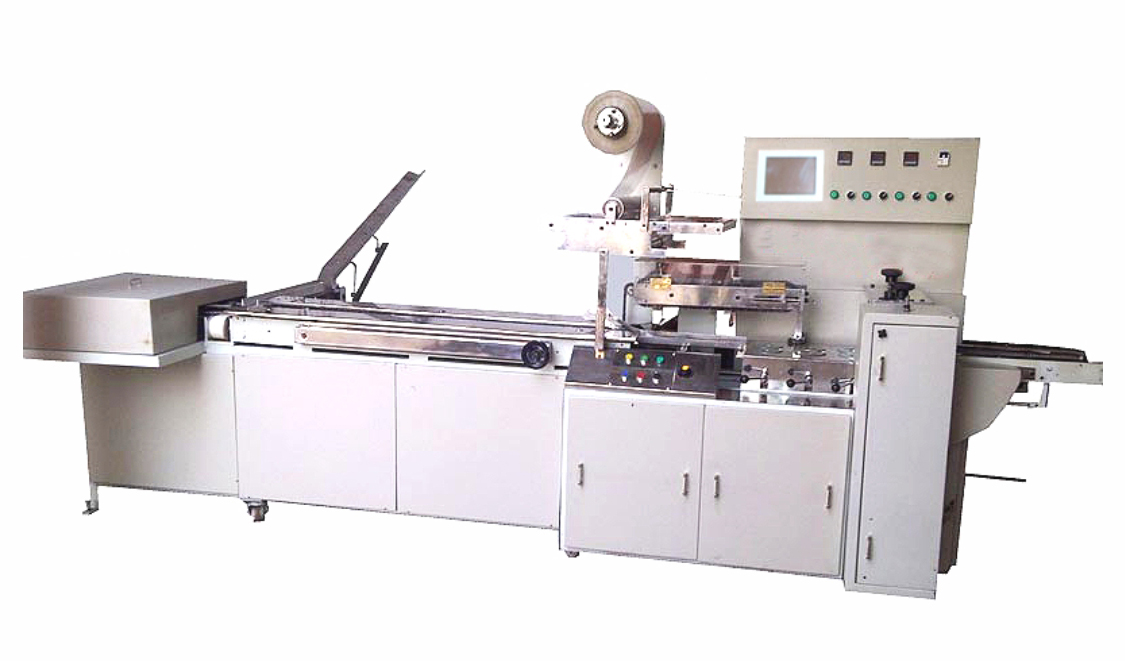

| Control | Plc control |

| Motor | 1/2 hp, 1/2 hp (conveyor) |

| Mode of operation | Pneumatic |

| Weighing | Manual weight (2lab:req) |

| Heating system | Hot bar induction heating |

| Coding | Pneumatic |

| Packing material | Laminated films |

| Power required | 420v, 3ph, 50hz, 5hp |

| Compressed air | 2cfm at 6bar pressure |

| Max. output | 15-25 packs/min |

| Film size (mm) | w 60-360 l 30-250 |

| Weighing range | up to 25g - 250g* |

| Weight | 400kg |

| Model | Cpm-ps-001 |

| Filling/weighing range | 5g-500g* |

| Packaging speed | 20-40 pkt/min |

| Control | Plc control |

| Operation | Pneumatic |

| Packaging material | Laminated film |

| Reak core dia | 70-76 mm |

| Heating system | Hot bar induction heating |

| Motor & power | 1/2 hp 220v ac single phase |

| Heater load | 50 watts x 4 no. of heaters |

| Material loading | Manual, scrue / vaccum loader |

| Compressed air required | 2cfm at 6 bar pressure |

| Dimension (approximate) | 1800w x 1800l 3600h (mm) |

| Availably in variety of models | 5g-200g* 200g - 500g* |

| Packaging film size in (mm) | w: 200 to 360* l: 30 to 250* |

| Drive | Ac drive / servo drive |

| Motor | 2 hp 220v single phase |

| Diameter roller | 6no (4 cold & 2 hot) |

| Sealer | 2 pieces |

| Diameter roller | 6 pieces |

| Controllers | p.i.d |

| Sealers body | can be adjusted up and down as per requirements |

| Control | plc |

| Line change | Gear system |

| Weighing | Number of pieces only |

| Feeding | Single feeder in the machine |

| Machine dim | 13 l-5w-h5 (feet) |

| Weight | 700kg - 800 kg apx |

| Drive | Ac drive / servo drive |

| Motor | 2 hp 220v single phase |

| Diameter roller | 4no (2 cold & 2 hot) |

| Sealer | 2 pieces |

| Diameter roller | 6 pieces |

| Controllers | p.i.d |

| Weighing | Number of pieces only |

| Feeding | Manual |

| Machine dim | 3120 l-1150w-h1580 (mm) |

| Weight | 400kg - 500kg apx |

Specifications

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm - Min. = 240 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal or Side Seal Pouch |

| Electrical Supply | 230 V/A.C./Single Phase/50 Hz |

| Power consumption | 2 KW |

| Weight | 600 Kg. (Approx) |

| Dimension | Depth:850mmW,910mmH,230 L |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

Filling Range

200ml to 1Ltr

Maximum Output

1000 to1200 Pouches per hour

Feature

Fully automatic Operated Mechanical machine with latest technology injection system. As per customers requirement REQUIRED ATTACHMENT cooling water Requirement 200 Lts / Hour @ 5 degree centigrade, Servo Stabilizers.

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 2 KW, Weight : 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

| Filling Range | 200ml to 300ml |

| Maximum output | 800 to 900 pouches per hour |

| Packing Material | Heat sealable LAMINATED films |

| Feeding System | Pneumatic |

| Roll Width: Max | 90/200mm |

| Sealing Type | Hot Bar |

| Pouch Type | Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Weight | 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L |

| Accuracy | +/- 2% |

| Filling Range | 1g to 200g |

| Maximum output | 800 to 900 pouches per hour |

| Packing Material | Heat sealable LAMINATED films |

| Feeding System | Pneumatic |

| Roll Width: Max | 90/200mm |

| Sealing Type | Hot Bar |

| Pouch Type | Side / Center Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 3KW |

| Weight | 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L |

| Accuracy | +/- 2% |

| Filling Range | 1g to 200g |

| Maximum output | 1000 to 1200 pouches per hour |