- India’s Leading Industrial Solution Provider

- Ink jet Printer

- Batch Coder Hot Ink Roller

- Manual Ribbon Coder

- Hot Ink Coding (Automatic Packaging)

- Ribbon Flow Pack Coding (Automatic Packaging)

- Ribbon Flow Pack Coding

- Numax Coder , Handy Coder

- Induction Sealer

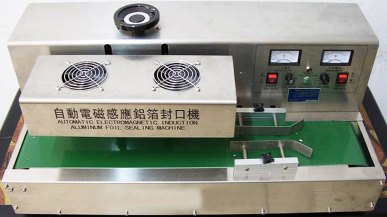

- Automatic Induction Sealer

Categories

The World Leader in Coding

The World Leader in CodingHitachi, which manufactured the first Japanese Industrial Ink Jet Printer in 1975 has boasted of a high achievement worldwide ever since, not to mention the Japanese market as reliable and leading brand of coating

- 3/4 Line Printer

- Low Maintain Cost

- Maintain Free

- LCD Display Touch Screen

- Installation well be done in

- On Line & Off Line

- Packaging Line

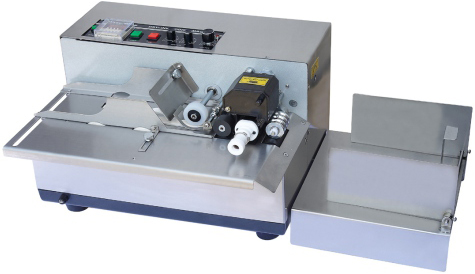

Model BC 810 / BC 600

- Ac 220 /50,Power:230W,

- Printing Speed :20-100p/min

- Pouch Size: L 60-600 W 50-300 (BC 810) L50-500 W30-190mm (BC 600)

- Letter Size: 2,3 mm Brass Letter

- Ink: Hot Ink Roll Catridge

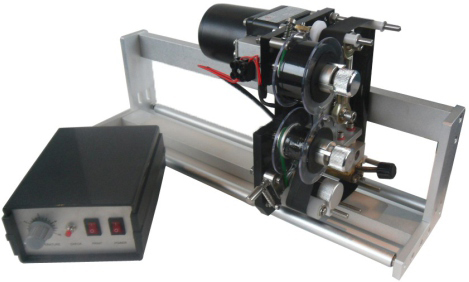

HP 241 B

HP 241 BHitachi, which manufactured the first Japanese Industrial Ink Jet Printer in 1975 has boasted of a high achievement worldwide ever since, not to mention the Japanese market as reliable and leading brand of coating

- Ac 220 /50,

- Power:230W,

- Letter Size: 2,3 mm

- Printing Size 1-4 Line: Brass Letter,

- Printing Speed :20- 50p/min

- Ink: Hot Foil Ribbion

HP 241

- Ac 220 /50,Power:230W,

- Printing Speed :10- 25p/min

- Printing Size 1-3 LINE: 15 CH,

- 4 X 35 MM: L50-500 W30-190mm

- Letter Size: 2,3 mm

- Brass Letter, Ink: Hot Foil Ribbon

HP 241

- Print Area1-5 line

- Printing Speed: 0-300 ppm

- Printing Area: 40*60 mm

- Film Driven

- LED display

- Ac 220 /50,Power:230W,

- Print Area: 1-4 line

- Printing Speed: 0-300 ppm

- Letter Size: 2,3 mm

- Brass Letter . Ink: Hot Foil Ribbon

- Printing Size: 1-5 LINE

- Letter Size: 2,3,4 mm

- Ink: Non Porus

- Size: 1", 3", 5", 7"(w) 8", 10 (L)

- Catridge: Porus & Non Porus

- Type set: Rubber Grued

- Voltage : Ac 220 /50

- Power : 600W

- Sealing Dia.: 20-100 / 20-140 mm

- Speed : 5-20(Min)

- Net Weight: 5Kg*

Model SPIS-200C

- Voltage (V/Hz) 220V/50, Power(W) 1.5KW

- Heal diameter : 20-135 (mm)

- Delivering speed 20-135

- Vessel height 0-10 mt/mint.

- Dimension(LxW H) 1150x480x400

- Weight(kg) 45kg

- Capacity 150pc./mnt(with diameter 100mm,flat capped and PE bottle)

Specifications

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm - Min. = 240 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal or Side Seal Pouch |

| Electrical Supply | 230 V/A.C./Single Phase/50 Hz |

| Power consumption | 2 KW |

| Weight | 600 Kg. (Approx) |

| Dimension | Depth:850mmW,910mmH,230 L |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

Filling Range

200ml to 1Ltr

Maximum Output

1000 to1200 Pouches per hour

Feature

Fully automatic Operated Mechanical machine with latest technology injection system. As per customers requirement REQUIRED ATTACHMENT cooling water Requirement 200 Lts / Hour @ 5 degree centigrade, Servo Stabilizers.

Product Range

Milk, Butter Milk, Juice Water, Liquids

Filling Range

200ml to 1ltr.

Maximum Output

10000 to120 Pouches per hour

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm - Min : 240 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Ele. Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power | 2 KW, Weight : 200-300 Kg(App) |

| Dimension | D : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

Feature

Fully automatic Operated Mechanical machine with latest pneumatics injection system. As per customers requirement REQUIRED ATTACHMENT cooling water Requirement 200 Lts / Hour @ 5 degree centigrade.

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 325 mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 2 KW, Weight : 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

| Filling Range | 200ml to 300ml |

| Maximum output | 800 to 900 pouches per hour |

| Packing Material | Heat sealable LLD films |

| Feeding System | Gravity flow |

| Roll Width: Max | 80/90/100mm |

| Sealing Type | Impulse Sealing |

| Pouch Type | Center Seal / Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 2 KW, Weight : 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L * |

| Film Quality | LLD Film Rolls |

| Accuracy | +/- 2% |

| Filling Range | 200ml to 300ml |

| Maximum output | 1000 to 1500 pouches per hour |

| Packing Material | Heat sealable LAMINATED films |

| Feeding System | Pneumatic |

| Roll Width: Max | 90/200mm |

| Sealing Type | Hot Bar |

| Pouch Type | Side Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Weight | 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L |

| Accuracy | +/- 2% |

| Filling Range | 1g to 200g |

| Maximum output | 800 to 900 pouches per hour |

| Packing Material | Heat sealable LAMINATED films |

| Feeding System | Pneumatic |

| Roll Width: Max | 90/200mm |

| Sealing Type | Hot Bar |

| Pouch Type | Side / Center Seal Pouch |

| Electrical Supply | 230 V/A.C. / Single Phase / 50 Hz |

| Power Consumption | 3KW |

| Weight | 300 Kg(Approx) |

| Dimension | Depth : 850mm W, 910mm H, 230 L |

| Accuracy | +/- 2% |

| Filling Range | 1g to 200g |

| Maximum output | 1000 to 1200 pouches per hour |